VRS Series Vacuum Reflow Oven

Zero-Oxygen Precision, Powering Global Smart Manufacturing!

Equipment introduction

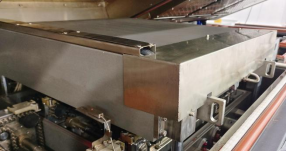

The Sun yan In-line Vacuum Reflow Oven is a high-end system specifically designed for high-precision electronic soldering processes. It is widely used in fields requiring high reliability, such as aerospace, automotive electronics, medical devices, semiconductor packaging, and defense industries. This solution enables automated in-line mass production, reducing manufacturing costs while achieving ultra-low void rates—with total void area optimized to be less than 1%.

Key Features

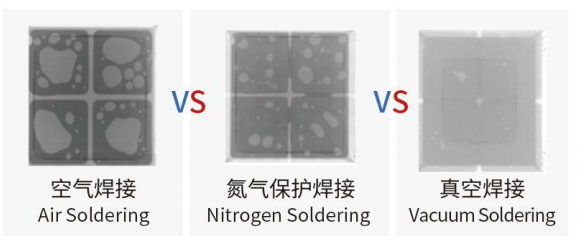

l Meets advanced packaging reflow process requirements, utilizing vacuum technology to significantly reduce soldering void rates;

l Integrally formed high-sealing vacuum chamber with a vacuum level of up to 3 mbar;

l Full-process nitrogen protection combined with vacuum technology to achieve optimal atmosphere control;

l Multi-zone independent precision temperature control, combining hot air and radiation in the vacuum zone to accurately achieve complex temperature profiles;

l Multi-stage transmission system with a minimum gap of 18 mm between each stage;

l Innovative furnace chamber structure design with multi-layer insulation, effectively reducing the working environment temperature;

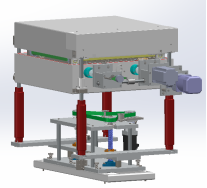

l Fully modular design for convenient and quick maintenance, reducing maintenance time and costs.

Highlights1. Nitrogen + Vacuum Atmosphere Combined with Multi-Stage Temperature Control Process Achieves Low-Void and High-Reliability Soldering!l Integrated furnace structure maintains oxygen concentration as low as 100ppm throughout the process.l The seamless vacuum chamber achieves a vacuum degree of up to 3mbar.

l Independent and precise temperature control for preheating, soldering, and vacuum stages enables accurate programming of temperature and pressure.

2. Stable Conveyance System with Multi-Section Design and Minimal Interfacing Spacing

l Sturdy Aviation Aluminum Rails + Roller Chains ensure stable and reliable operation.

l Minimum Conveyance System Spacing of 18mm prevents board jamming and enables smoother product transitions.

l Modular Conveyance System allows for independent and convenient maintenance of the vacuum zone transport section.

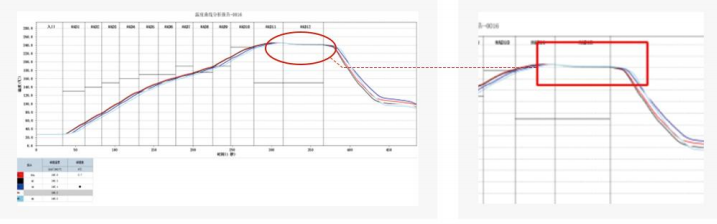

3. Accurate Temperature Control in the Vacuum Stage to Achieve the Optimal Process Curve

l The vacuum zone utilizes enhanced heat conduction and radiation heating, achieving an industry-leading minimal temperature difference (ΔT) for the product in the vacuum section.

l High-Performance PID Temperature Control Module enables precise temperature regulation.

4. Novel Flux Decomposition and Removal System for a Cleaner Furnace

l A new catalytic pyrolysis technology for flux removal, unlike traditional phase-change condensation recovery, enables maintenance-free or minimal maintenance operation.

l Efficient collection, decomposition, and removal of flux result in a cleaner furnace atmosphere and improved soldering quality.

l The process is environmentally safe; the decomposed gases meet direct emission standards, eliminating secondary pollution.

l The decomposition module requires no residue cleaning and only needs annual maintenance, significantly reducing upkeep costs.

Related Products

-

TB Series Inline Vertical Curing Oven

Learn more

-

TB-450-2 Customized Vertical Curing Oven

Learn more

-

TC Series Lead Free Convection Reflow Oven

Learn more

-

TH Series Fully Automatic Lead-Free Nitrogen Reflow Oven

Learn more

-

TS Series Semiconductor Packaging Reflow Oven

Learn more

-

VRS Series Vacuum Reflow Oven

Learn more