TB Series Inline Vertical Curing Oven

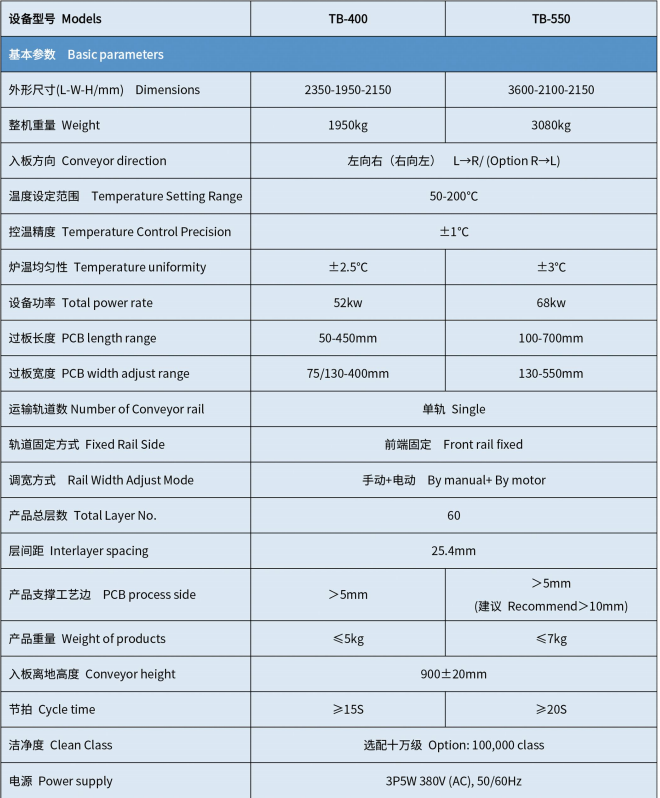

Vertical curing oven is a specialized equipment designed for curing processes. It utilizes vertical hot air circulation to heat and rapidly cure materials (e.g. coatings, adhesives, glues). It’s widely used in industries such as new energy, smart phones, tablets, smart home appliances, automotive electronics, medical devices, and semiconductor packaging. Compared with offline curing oven and tunnel ovens, it can effectively increase production capacity, significantly reduces floor space, and offers flexibility in production line layout, especially for products with long curing time in the oven.

Key Features

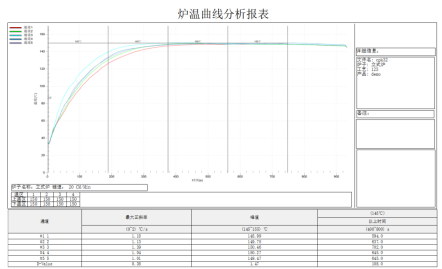

l Precise Temperature Control: Multi-point sensing and intelligent algorithms ensure uniform and stable temperatures for high-precision curing.

l High Efficiency & Energy Saving: Forced convection technology shortens curing time and boosts overall productivity.

l Space-Saving Design: Vertical structure minimizes footprint, ideal for limited-space production environments.

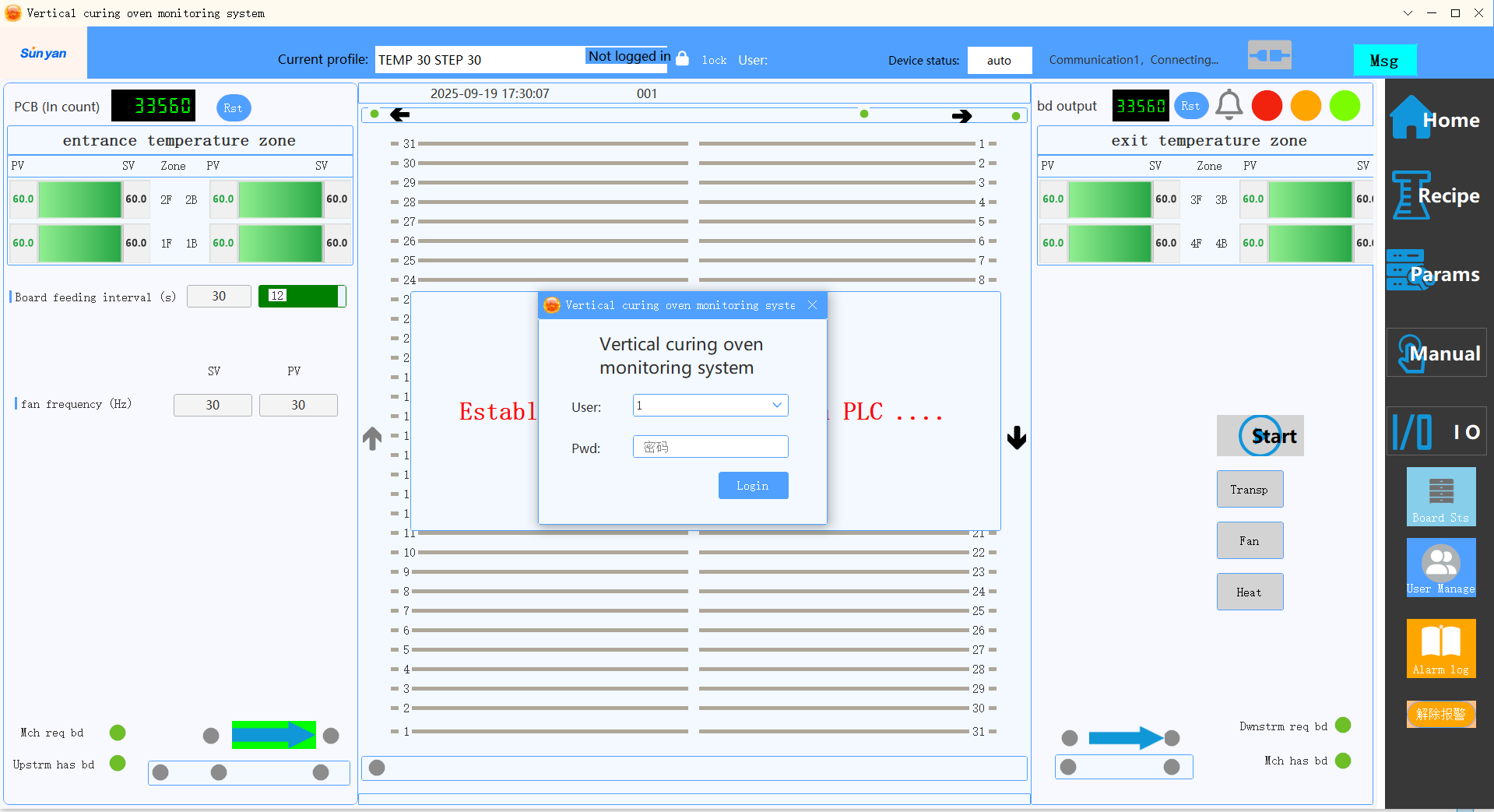

l Smart Automation: Automated loading/unloading and MES integration enable remote monitoring and data traceability.

l Flexible Customization: Supports personalized parameter, structural, and functional configurations to meet diverse needs.

l Safe & Reliable: Built-in safety mechanisms (over temperature, power failure, jam detection) ensure operational safety.

l Easy Maintenance: Modular design and user-friendly interface simplify maintenance and enable efficient troubleshooting.

Highlights

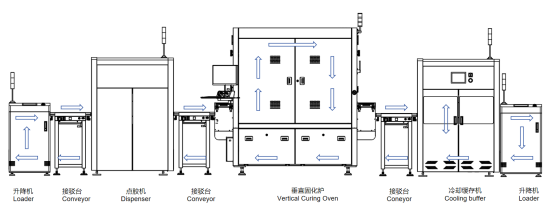

1. Fully automated production line layout: supports bottom-side fixture return and enables unmanned loading/unloading;

Production line diagrammatic drawing

2. Compared to offline ovens, it eliminates repeated handling, ensures more stable temperature, and delivers superior curing quality.

3. Flexible Design and Customization: Offers personalized process parameter configurations, equipment dimension adjustments, and expandable functionalities based on client needs. Optional configurations include nitrogen vertical curing ovens and dual-track vertical ovens and so on.

4. Smart Monitoring: Integrated MES system supports remote monitoring, data traceability, and fault alerts, with real-time process display on the main software interface.

Related Products

-

TB Series Inline Vertical Curing Oven

Learn more

-

TB-450-2 Customized Vertical Curing Oven

Learn more

-

TC Series Lead Free Convection Reflow Oven

Learn more

-

TH Series Fully Automatic Lead-Free Nitrogen Reflow Oven

Learn more

-

TS Series Semiconductor Packaging Reflow Oven

Learn more

-

VRS Series Vacuum Reflow Oven

Learn more