- Home >> Product Centre >> Reflow Oven

TS Series Semiconductor Packaging Reflow Oven

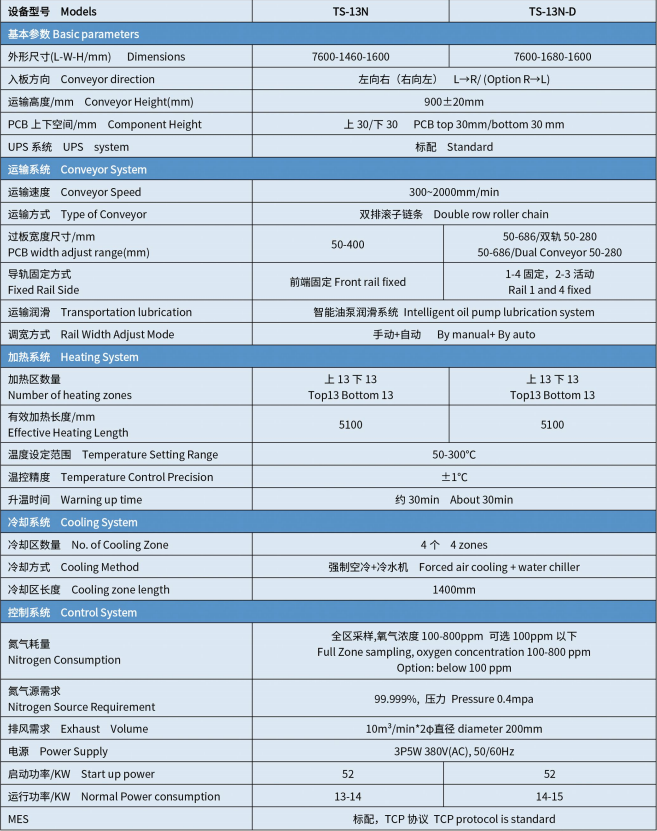

TS Series Semiconductor Packaging Reflow Oven deliver high precision, efficiency, and intelligent performance, ideal for advanced applications in 5G, automotive electronics, medical devices, and semiconductors. With smart control, dual-lane throughput, and precision nitrogen soldering, they ensure superior soldering quality, higher productivity, and enhanced reliability to meet the demands of high-end manufacturing.

Equipment Introduction

TS Series Semiconductor Packaging Reflow Oven deliver high precision, efficiency, and intelligent performance, ideal for advanced applications in 5G, automotive electronics, medical devices, and semiconductors. With smart control, dual-lane throughput, and precision nitrogen soldering, they ensure superior soldering quality, higher productivity, and enhanced reliability to meet the demands of high-end manufacturing.

Key Features:

l High production capacity, with a normal production chain speed of up to 160cm/min;

l Low energy consumption, new thermal engineering management system, effectively reducing costs.

l Professional response to high-speed production and high-precision PCB packaging processes, meeting customers' high-end process requirements.

l Strong temperature control capability, high temperature control accuracy, with a set and actual temperature difference of within 1.0 ℃; The temperature fluctuates by 1.5 ℃ from no-load to full load.

l Rapid heating, the heating module can reach working temperature within 15-20 minutes, reducing standby energy consumption.

l New insulation technology combined with a completely new furnace structure design can effectively reduce the furnace surface temperature and lower heat loss

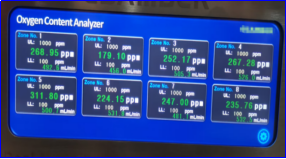

l The nitrogen concentration throughout the process is quantitatively controllable, with independent inspection displays for each temperature zone, which can control the oxygen concentration range within 50-200PPM.

l Latest cooling technology, optional multi zone double-sided cooling; The maximum effective cooling length is 1400mm; ensuring rapid cooling of the product and the lowest outlet temperature.

l Multi stage flux recycling system, multi-point collection, fully improves the recycling rate, reducing maintenance time and frequency for customers.

l Dual speed regulation, single machine cost, double production capacity, energy saving up to 65%.

l Support MES docking, can cooperate with the development of SECS/GEM protocol, achieve cloud monitoring of temperature curves and process traceability.

Highlights:

More Precise Temperature Control and Thermal Management

l Multi-Zone Independent Control: Supports complex temperature profiles, compatible with lead-free, high melting point solder pastes, and special alloys such as SAC305 and BiSn.

l Three-phase heating wire heating: Stable heating output enables precise temperature control; load balancing minimizes grid impact and ensures excellent stability.

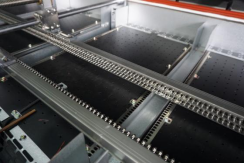

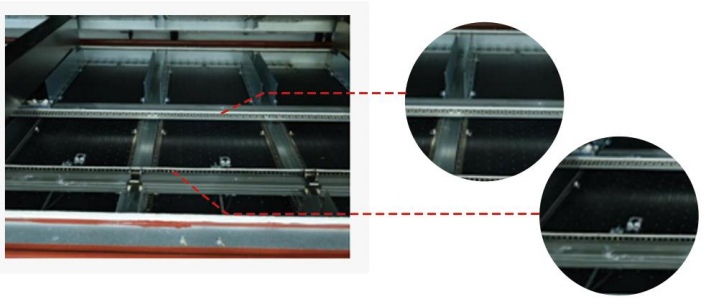

Stable and Reliable Structural Design

l 8 mm aviation-grade aluminum rectifier plate with far-infrared nano coating, combined with high-temperature furnace materials and ceramic fiber insulation: corrosion-resistant, oxidation-resistant, and long service life.

l Durable guide rails: dual-side hardened rails with automatic oil-pump lubrication, ensuring smooth and reliable operation.

Intelligence & Data Management

l Smart Temperature Monitoring: An optional high-precision real-time temperature monitoring system ensures precise control over every degree of variation and full mastery of welding quality.

l Data Traceability: Intelligent data traceability system supports MES integration for transparent and smart production management. Optional SECS/GEM Communication Interface: Enables efficient connectivity and data exchange with semiconductor manufacturing equipment.

Full-area Nitrogen Coverage

l Complete nitrogen coverage throughout the furnace, with residual oxygen levels as low as within 100 ppm.

l Full-zone nitrogen display and monitoring.

Related Products

-

TB Series Inline Vertical Curing Oven

Learn more

-

TB-450-2 Customized Vertical Curing Oven

Learn more

-

TC Series Lead Free Convection Reflow Oven

Learn more

-

TH Series Fully Automatic Lead-Free Nitrogen Reflow Oven

Learn more

-

TS Series Semiconductor Packaging Reflow Oven

Learn more

-

VRS Series Vacuum Reflow Oven

Learn more