- Home >> Product Centre >> Reflow Oven

TH Series Fully Automatic Lead-Free Nitrogen Reflow Oven

Outstanding performance, precision and efficiency — fulfilling your dual pursuit of quality and production capacity

Key Features

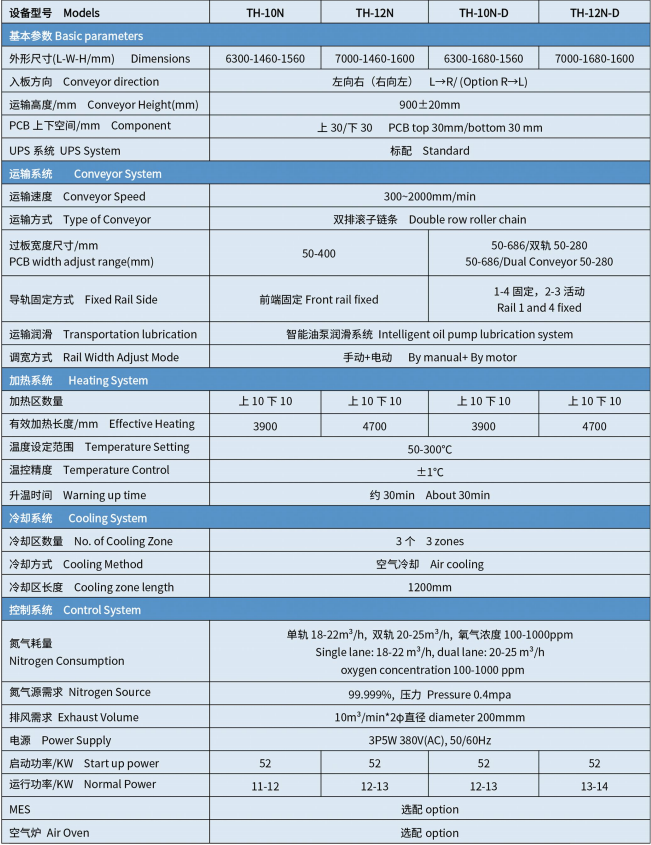

l 10/12 Zone Single or Dual lane Air or Nitrogen Reflow soldering with Flexible Configuration Options.

l High production efficiency and good soldering quality, significantly shortening the production cycle and effectively saving time and costs.

l Energy-saving and environmentally friendly — the new cooling structure reduces heat loss, while more thorough flux recovery lowers air pollution.

l High-precision soldering supported by advanced temperature control and heat-transfer technology ensures soldering quality and boosts productivity.

l Excellent stability with a focus on automation and stable conveying ensures consistent production efficiency and product quality.

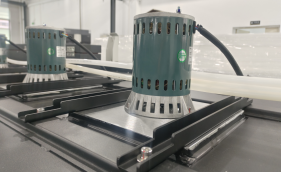

l Heavy-duty conveying using a dual-row stainless-steel ball chain, providing higher load capacity, cleaner operation, and greater durability and stability.

l Multi-layer insulated furnace design keeps the furnace surface temperature low with minimal heat loss.

l Outstanding cooling performance — multi-zone dual-sided cooling with a maximum cooling length of 1200 mm enables rapid product cooling.

l Highly efficient flux recovery, with multi-point collection to improve recovery efficiency and reduce customer maintenance time and frequency.

l Low nitrogen consumption, thanks to a fully sealed furnace design that effectively prevents nitrogen leakage; oxygen content can be reduced to as low as 100ppm.

Highlights:

Improved Production Efficiency

lHigh welding speed enables rapid processing of large volumes.

lShortens production cycles, saving time and operational costs.

Exceptional System Stability

lDesigned with high automation and stable material transport.

lStainless steel double-row ball chain ensures cleaner, more stable, and more durable conveyance.

Multi-Layer Insulated Furnace Design

lLow surface temperature of the furnace.

lSignificantly reduced heat loss, improving thermal efficiency.

Superior Cooling Performance

lMaximum effective cooling length up to 1200mm, ensuring rapid product cooling to minimum outlet temperatures.

lThe nitrogen reflow oven comes standard with a 5P water chiller, delivering efficient heat dissipation and a more stable cooling profile.

Low Nitrogen Consumption

lFully enclosed chamber design effectively retains nitrogen.

lNitrogen consumption remains at only 18–25 m³/h in 100–1000 ppm oxygen environment.

Related Products

-

TB Series Inline Vertical Curing Oven

Learn more

-

TB-450-2 Customized Vertical Curing Oven

Learn more

-

TC Series Lead Free Convection Reflow Oven

Learn more

-

TH Series Fully Automatic Lead-Free Nitrogen Reflow Oven

Learn more

-

TS Series Semiconductor Packaging Reflow Oven

Learn more

-

VRS Series Vacuum Reflow Oven

Learn more