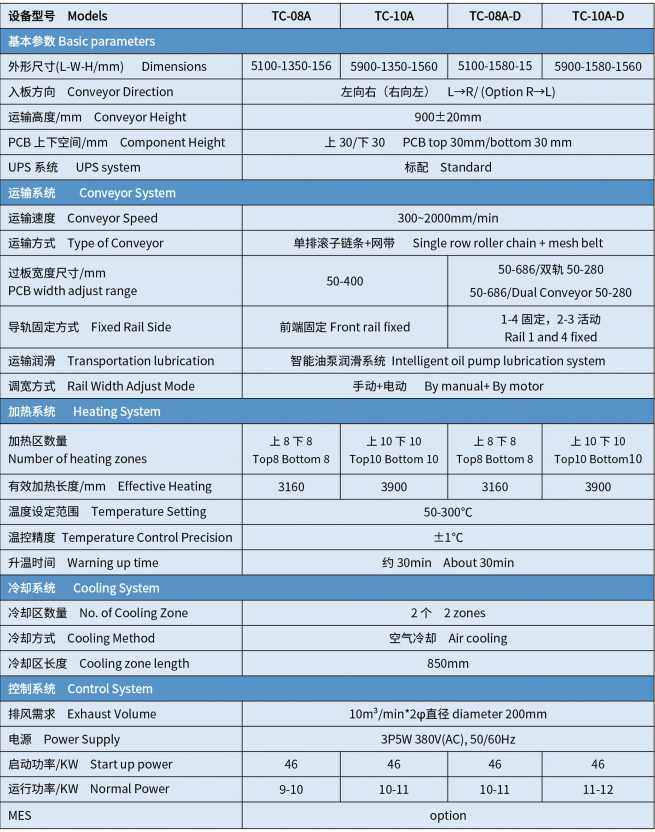

- Home >> Product Centre >> Reflow Oven

TC Series Lead Free Convection Reflow Oven

Stable and reliable, economical and practical, good welding quality

Key Features

l Fully meet the requirements of various lead-free soldering processes.

l Windows 10 operating system, with a Chinese and English interface, easy to operate and learn.

l Exquisite body shape, shorter device dimensions, and longer heating dimensions.

l Standard 8/10 temperature zone air furnace, precision hot air management system makes hot air convection more efficient and heat compensation faster.

l PLC ten PID closed-loop temperature control, stable and reliable performance, high temperature control and curve repeatability accuracy.

l Equipped with fault diagnosis function, it can display various faults and automatically display and store them in the alarm list.

l The new integrated full welding furnace body structure design, multi-layer insulation, effectively reduces the working environment temperature.

l Fully modular design, convenient and fast maintenance, reducing maintenance time and costs.

l The guide rail adopts special hardening treatment, which is sturdy and durable.

l The transportation chain adopts stainless steel ball single row chain, which runs cleaner, more stable, and more durable.

l Intelligent chain lubrication system, with software intelligent reminder to add when the oil level is low.

l Active exhaust design, more thorough recovery of flux in the furnace.

l Configurable sensors can monitor the status of motors and heating tubes in real time to prevent sudden failures, and software pop ups provide maintenance reminders.

l Convenient modular design for cooling and recycling areas, with quick detachable maintenance.

Highlights

1. Compact & Efficient Design

The heating zone is longer, the equipment is shorter, Achieve large production capacity with smaller footprint.

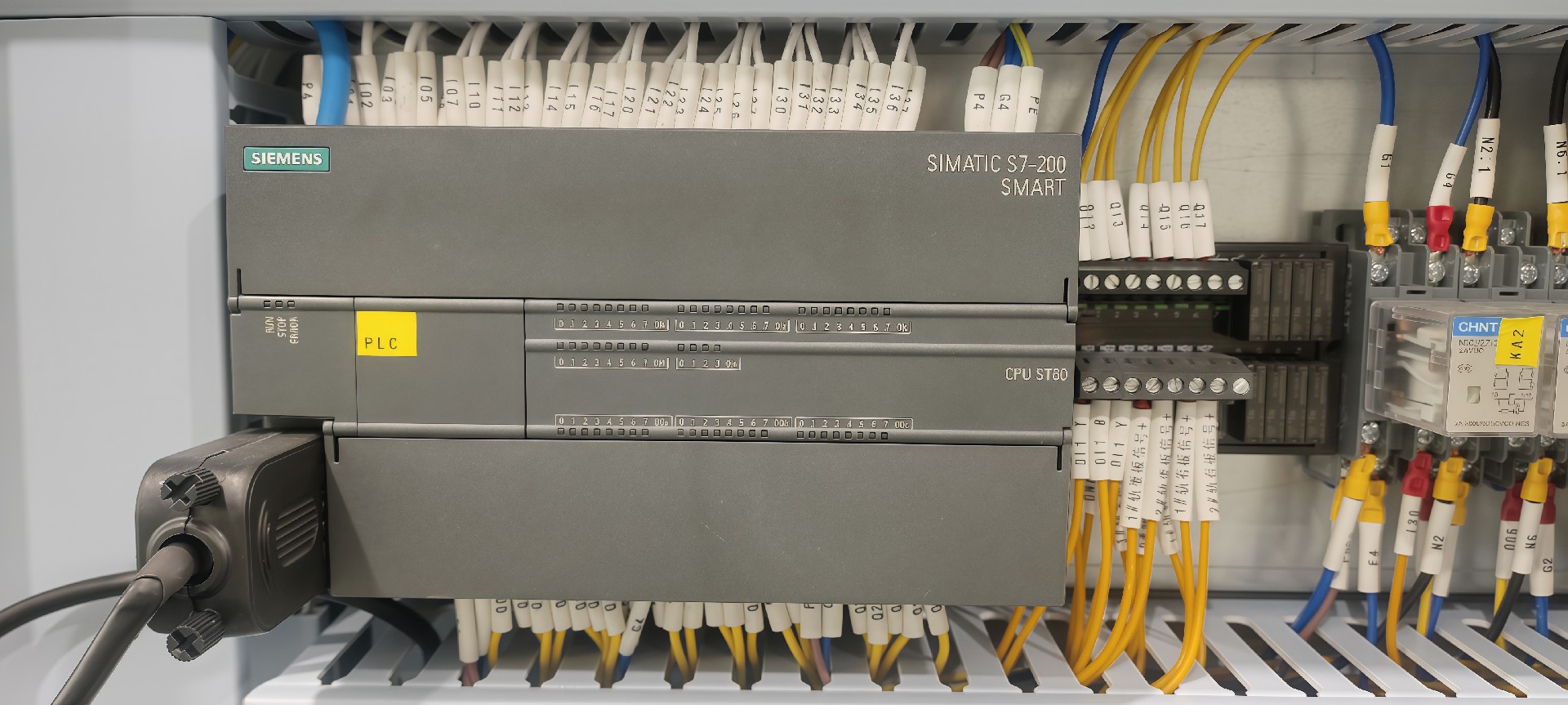

2. First-class brand PLC, Precision Temperature Control

Major control and key components are sourced from internationally renowned original brands, ensuring more stable control.

Siemens PLC offers stable and reliable performance, with high precision and repeatability in temperature control and profiling.

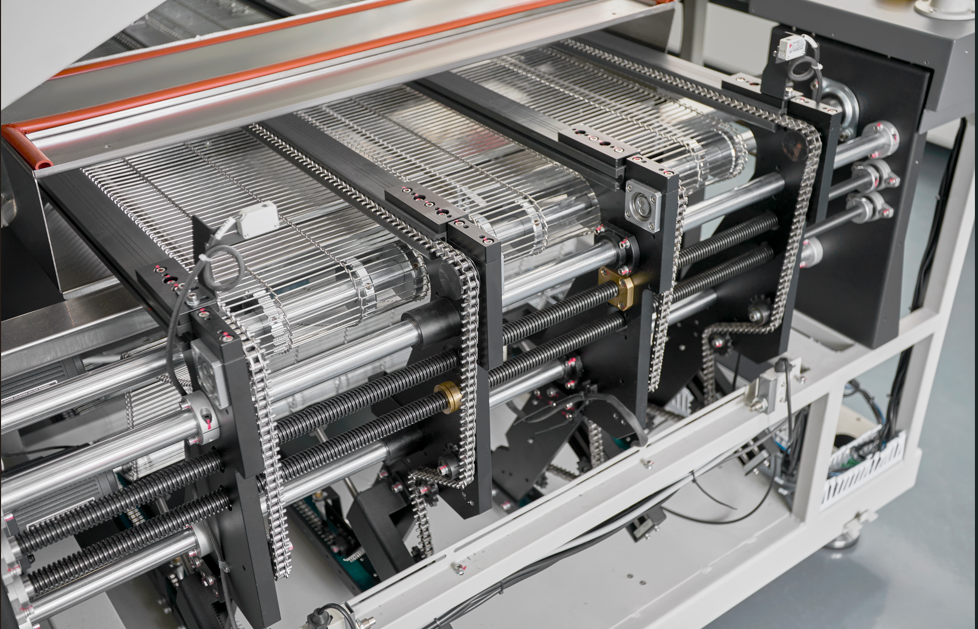

3. Durable and stable transmission system

Hardened guide rails for maximum durability.

The single-row stainless steel ball chain conveyor delivers cleaner, smoother, and more reliable transport.

4. Excellent flux recovery efficiency

New flux recycling system, more thorough recycling of flux, tool free quick release design, more convenient Maintenance.

5. Active exhaust system

The exhaust system is equipped with an active fan and a unique funnel collection exhaust box design,

Reduce the overflow of hot air at the inlet and outlet of the equipment, and recover it more thoroughly.

Related Products

-

TB Series Inline Vertical Curing Oven

Learn more

-

TB-450-2 Customized Vertical Curing Oven

Learn more

-

TC Series Lead Free Convection Reflow Oven

Learn more

-

TH Series Fully Automatic Lead-Free Nitrogen Reflow Oven

Learn more

-

TS Series Semiconductor Packaging Reflow Oven

Learn more

-

VRS Series Vacuum Reflow Oven

Learn more