TB-450-2 Customized Vertical Curing Oven

Customized Non-Standard Solutions, Designed for Large-Size/Heavy PCBs & Special Applications

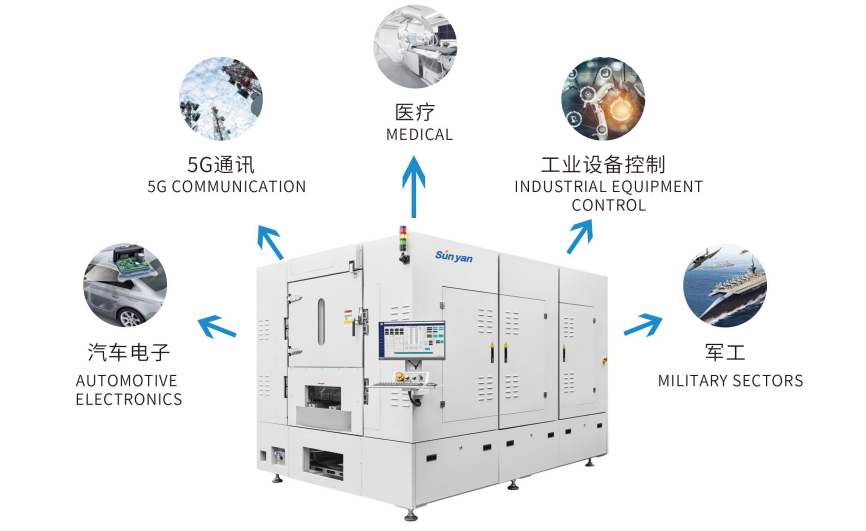

TB-450-2 is a vertical curing system specifically designed for oversized boards, heavy-duty PCBs, and non-standard components. It features a vertical structure with hot air circulation heating technology and a high-efficiency transport design that supports dual-board placement per layer, effectively doubling production capacity. With a modular design, it can be flexibly adapted to the specialized needs of industries such as automotive electronics, 5G communication, medical, and military sectors. The system offers fully customized whole production line solutions from oven dimensions, carrier structure and process temperature.

Application Fields

Key Features

l Dual-fixture placement per layer with flexible spacing design

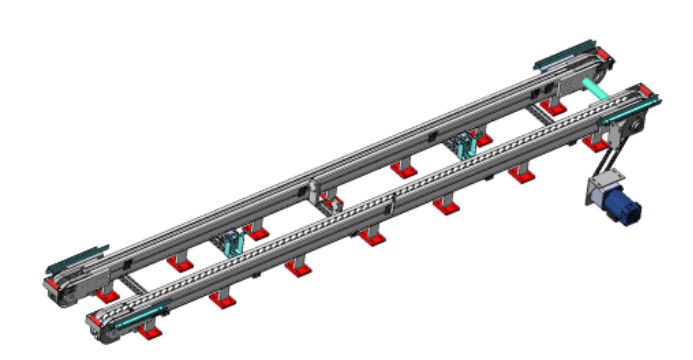

l Heavy-duty fixed-rail transport system supports oversized and heavy boards; intelligent transfer system with precise detection

l Fully automated line integration, supports bottom fixture return for unmanned loading and unloading

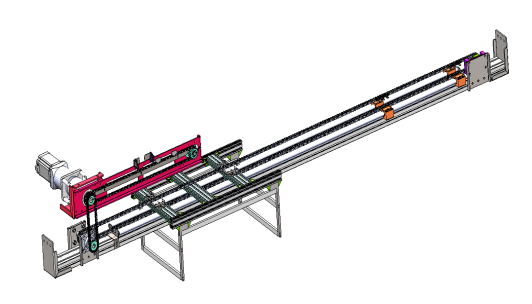

l Stable sliding rail system with precise push mechanism

l High throughput with low energy consumption

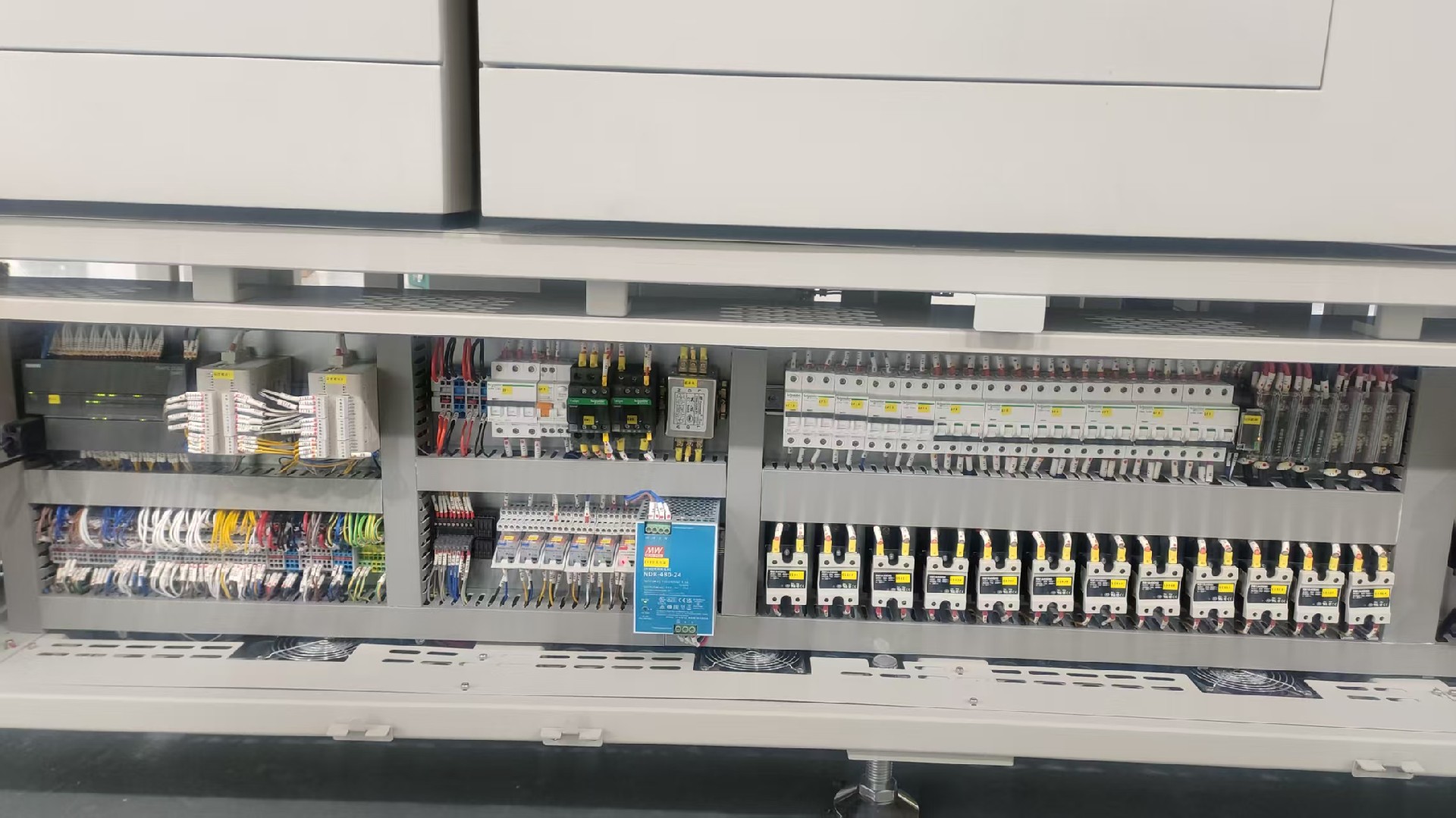

l Separated high and low voltage zones for enhanced safety

Highlights:

1. The fixed rail structure supports up to 19 layers on a single side, with configurable skip-layer spacing to easily accommodate products of various heights and non-standard fixtures.

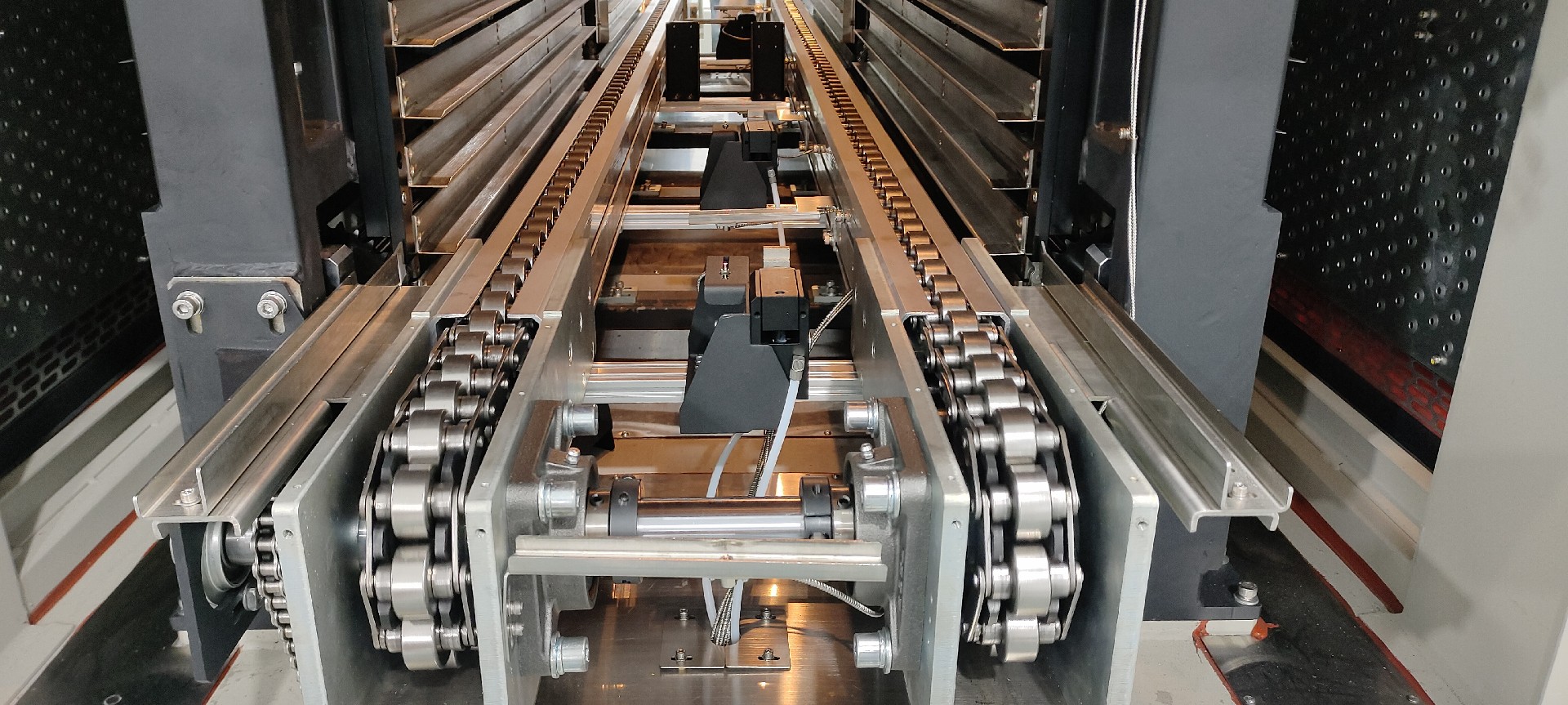

2. Fiber optic sensors are installed at the loading and unloading sections for precise positioning. Each layer can hold two fixtures simultaneously, improving throughput and space utilization.

3. Equipped with IGUS linear rails, the top transfer mechanism is driven by a stepper motor with a chain and sprocket system, ensuring structural stability and smooth transmission.

4. Fully automated production line integration supports bottom fixture return, enabling unmanned board loading and unloading.

Production Line Layout Plan

5. The electrical control cabinet features separated high and low voltage zones to reduce interference and enhance overall system stability and operational safety.

Related Products

-

TB Series Inline Vertical Curing Oven

Learn more

-

TB-450-2 Customized Vertical Curing Oven

Learn more

-

TC Series Lead Free Convection Reflow Oven

Learn more

-

TH Series Fully Automatic Lead-Free Nitrogen Reflow Oven

Learn more

-

TS Series Semiconductor Packaging Reflow Oven

Learn more

-

VRS Series Vacuum Reflow Oven

Learn more